Materials production from particles bio-cementation with liquid foam

Advisors: Olivier Pitois, Vincent Langlois (Navier), Marielle Gueguen (Univ. G. Eiffel/CPDM), Benjamin Carbonnier, Daniel Grande (ICMPE)

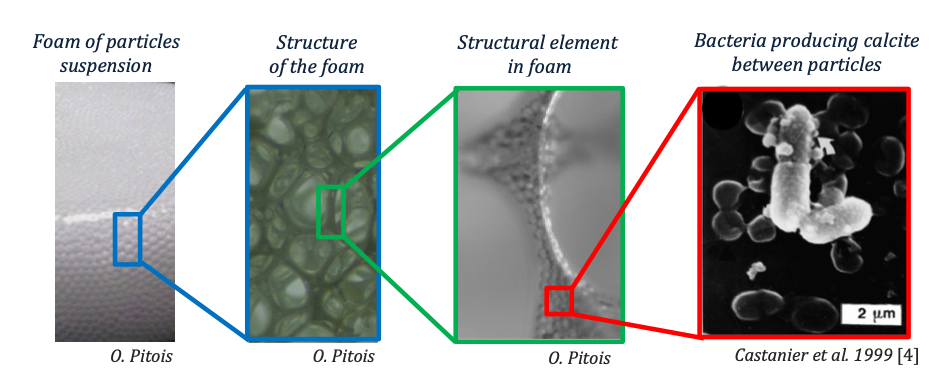

This PhD work focuses on the use of bacteria liquid foams combined with particles assemblies in order to produce materials. Two distinct situations are considered depending on the particle/bubble size ratio: (i) cementing foam within the porosity of granular media, and (ii) small particles forming a solid skeleton between the foam bubbles. Note that the first configuration is also relevant to develop new method for soil improvement, i.e. to confer mechanical cohesion to powdered soils. The intended effect of introducing bacteria into the formulation is the bio-cementation of the grains. In both cases, the production of calcium carbonate by the bacteria will act as glue between the grains and consolidate the granular structures.

The critical step of this study is related to developing active bacteria foaming solutions. This is done by measurements of bacterial activity within different surfactant solutions. With respect to situation (i) our current work is dedicated to the understanding of bubbles configurations within the pore space of granular assemblies. As a first result we have highlighted that such confined liquid foam offers significant amount of liquid contained in bridging areas at contact between the grains. It is to say that for classical bio-cementation in granular media [1] and soils [2], the produced solid cement is usually dispersed throughout the pore surface. Using the foam approach, the above-described configuration is expected to be a strong advantage for bacteria-induced mechanical improvement of soils. Up to now, configuration (ii) has never been considered as a strategy to elaborate material. We will take advantage of the jamming properties of granular suspensions when confined within the liquid foam pore space [3]. If required, gelling agents could be used to increase the foam stability during the stage of bacteria activity.

Figure 1. Illustration of the skeleton formed by small particles confined between foam bubbles.

Adding bacteria to the foaming solution could help cementing this skeleton.

References:

- L. Cheng, R. Cord-Ruwisch, et M. A. Shahin, « Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation », Can. Geotech. J., vol. 50, no 1, p. 81‑90, janv. 2013, doi: 10.1139/cgj-2012-0023.

- M. Medevielle, « Utilisation de la bioprécipitation de carbonates de calcium pour améliorer la qualité de granulats de béton recyclé », 2017.

- B. Haffner, Y. Khidas, et O. Pitois, « Flow and jamming of granular suspensions in foams », Soft Matter, vol. 10, no 18, p. 3277, 2014, doi: 10.1039/c4sm00049h.

- S. Castanier, G. Le Métayer-Levrel, et J.-P. Perthuisot, « Ca-carbonates precipitation and limestone genesis — the microbiogeologist point of view », Sediment. Geol., vol. 126, no 1, p. 9‑23, juill. 1999, doi: 10.1016/S0037-0738(99)00028-7.