Couche-limite et glissement des fluides à seuil

Advisors: Philippe Coussot (NAVIER), Philippe Basset (ESYCOM), Florence Rouyer (NAVIER), Julie Goyon (NAVIER), Tarik Bourouina (ESYCOM)

Summary:

The objective of this PhD was to put together the competences recently acquired by the team Rhéophysique of Laboratoire Navier on confined flows, by the team Physics of Porous Media on yield stress fluid flows and on surface treatment by ESYCOM. We intend to study in more details confined flows of yield stress fluids for which several questions need to be addressed: wall slip?, confinement effects? (i.e. invalidity of the macroscopic constitutive equation for small-scale flows), validity of the continuum assumption?

The first orientation of the work consisted to study wall slip of emulsions in simple shear (in recent years the wall slip of microgel suspensions has been widely studied by Michel Cloitre and co-authors). In that aim he first characterized the behavior of these materials with rough surfaces. Then the three research teams worked together on the determination of the most appropriate solid surfaces to study the impact of the roughness and wetting properties on wall slip. A major progress appeared with the possibility to use extremely smooth surfaces, made of silicium with a roughness of the order of the nanometer. It was then possible to show how the wall slip evolves when the roughness ranges from the nanometer to the hundred of microns (much larger than the droplet size): we observe a threshold of slip which increases from zero to the yield stress (no wall slip).

The second axis of this work is the study, by MRI, of flows through small (millimetric or smaller) conduits, in order to look at the validity of the constitutive equation under such conditions. The experiments are carried out in Nancy (LEMTA, Maude Ferrari). The results obtained allow to measure directly the local constitutive equation which may be compared favorably with the constitutive equation measured by conventional rheometry. So far no confinement effect was observed but the results allowed to measure the wall slip velocity, which appears to be in agreement with above data.

The last axis of work concerns a specific type of flow, i.e. elongation. Such flows with yield stress fluids have never been studied under appropriate condition. As a matter of fact when one tries to get such a flow by approaching or moving away two parallel plates separated by a volume of paste, one gets essentially a shear flow and finally a separation of the material in two conical volumes. Here it appears possible to get an elongational flow by taking advantage of the perfect wall slip obtained with the silicium surfaces. By programming an exponential variation of the separation velocity of the two plates we can impose a constant elongation rate. Among others this experiment will allow to check the validity of the 3D constitutive equation generally assumed for such fluids.

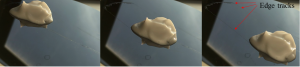

Recently we focused on the slip flow characteristics on smooth surfaces. We carried out systematic tests with a variety of materials and under different conditions. In particular we could show that the usual slip yield stress beyond which slip flow starts is not, as usually assumed, a critical stress to overcome to break some attachment of the suspended elements with the solid surface. It in fact corresponds to an edge effect, due to some impossibility of the line of contact to slip along the wall. We could show this by carrying out tests with parallel plates of different diameters (then we see that this slip yield stress decreases with the disk diameter, which means that it is not an effect taking place along all the surface of contact). This was confirmed by observations of the lateral tracks left along the edges (i.e. along the lateral lines of contact) of a sample slipping on the inclined smooth surface (see Figure 1).

Figure 1: Successive views of a heap of emulsion put on a smooth surface, at times: (a) 0, (b) 15.6 s, (c) 26 s.

By removing artefacts due to edge effects in rheometrical tests, we then show that the stress solely due to wall slip varies linearly with the slip velocity and corresponds to that needed to simply shear the interstitial Newtonian liquid in a layer of almost constant thickness (40 nm) for a wide range of materials with different structures, interaction types, and concentrations. This film thickness in fact corresponds to some average liquid thickness remaining between the (rough) jammed structure and the smooth wall.

Publications:

[1] X. Zhang, O. Fadoul, E. Lorenceau, P. Coussot, Yielding and flow of soft-jammed systems in elongation, Physical Review Letters, 120, 048001 (2018)

Editor’s suggestion: https://journals.aps.org/prl/highlights?page=3

[2] X. Zhang, E. Lorenceau, P. Basset, T. Bourouina, F. Rouyer, J. Goyon, P. Coussot, Wall slip of soft-jammed systems: a generic simple shear process, Physical Review Letters, 119, 208004 (2017)