Modélisation multi échelle du comportement thermomécanique et de l’endommagement des bétons incluant des matériaux à changement de phase microencapsulés

Advisors: Julien Yvonnet (MSME), Karam Sab (NAVIER), Mustapha Karkri (CERTES)

Brief summary:

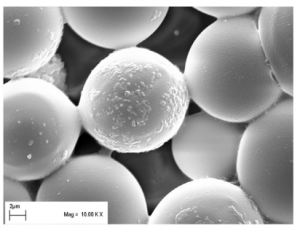

The storage of thermal energy is cruc ial to reduce CO2 rejects and the use of fossile energies. This storage can be performed in civil engineering structures such that concrete by e mbedding phase change materials. These Phase Change Materials (PCMs), like small Micronal® PCM-capsules , are promising in view of their high latent heat energy storage at temperatures close to the room temperature. However, incorporating microcapsules induces a reduction of mechanical properties within the structure and the cycles of fusion/solidification of paraffin can induce microcracking leading to: (a) damage within the structure; (b) leakage of paraffin reducing the energy storage capacities. The prediction of the coupled thermomechanical properties and damage in such new materials is thus crucial for their design. The objectives of the present project are: (i) to develop homogenization methods based on numerical techniques to predict the thermomechanical behaviour of composites materials containing phase change inclusions; (ii) to develop a numerical framework to simulate microcrackig in PCM reinforced concrete due to the cycles of phase change and possible leakage of the fluid within the cracks; (iii) to model the loss of efficiency of PCM due to leakage of liquid PCM through microcracks and diffusion within the porous matrix; (iv) Model the multiscale damage within such materials due to the different mentioned phenomena and propose upsca ling procedures for computing the behaviour at the scale of a structure. The different modelling steps will be completed, if possible, by experimental characterization and validation.

Figure 1: Paraffin microcapsules.

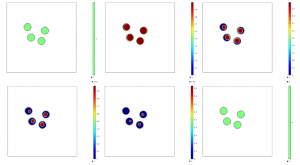

Different modelling and numerical simulation tools have been developed, including: (i) the development of a phase field code for simulating crack propagation ; (ii) the development of a diffusion model to simulate the leakage of liquid PCM within cracks ; (iii) the development of a code to simulate liquid-sold phase change in PCM capsules.

Figure 2: simulation of the liquid-solid phase change in PCM capsules embedded in a concrete matrix, evolution of the liquid concentration with respect to time.